52100 Steel

52100 steel carbon, high hardness and wear resistance. Chemical composition: C:1.00 Si:0.30 Mn:0.30 Cr:1.50

Steel 52100 carbon, high-content chromium, it is mainly used for field knives and tools that require high mechanical resistance. Gets a spectacular Mirror polished.

Its main features:

- High hardness.

- High mechanical strength.

- High retention of the cutting edge.

- Up to 70 HRC.

- Mirror polished very good.

- Low oxidation.

Chemical composition (%): C:1.00 Si:0.25 Mn:0.30 Cr: 1.50

This steel is recommended both for beginners as professionals, the degree of difficulty of work is low.

Supplied annealed (soft), to facilitate the work.

Heat treatment:

- Forging : 850 to 1050 ºC. Very slow cooling in furnace or insulation materials (sand, salt, mica).

- Normalizing : 650 ° C. To eliminate the structural tensions caused by forging or roughing. Preferred time, 1-2 hours.

- Hardening (oil) : 800 a 850 °C. Warming slow and progressive, keep at least 1 minute per millimeter. Cooling in oil to 210 - 250 ° C to reduce thermal shock, keep cool for 15 to 20 minutes. 63 To 66 HRC hardness. To achieve the 67 HRC, we recommend the warm water, with a temperature of 800 to 830 ° C.

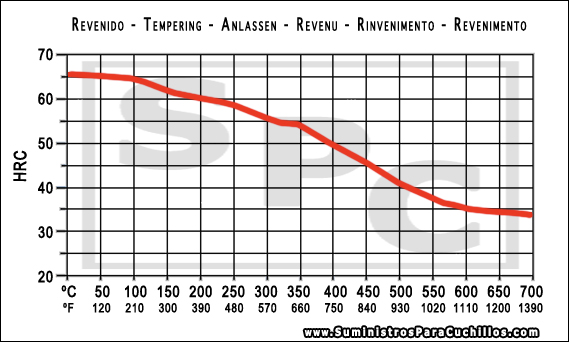

- Tempering : 150 a 250 ° C, for thicknesses up to 6 mm for 45 minutes. Slow heating up to reach the temperature(see the tempering chart), 59 To 65 HRC hardness.

Quenching and tempering is recommended in atmosphere conservative, see tempered blade.

This is the recommended thermal treatment, there are others. Temperatures, times or form of realization of it, depending on your needs you can vary or experience in such process.

MATERIAL CUT THROUGH MECHANICAL PROCESS MAY HAVE BENT (NOT COMPLETELY FLAT).