420 stainless steel

Steel stainless 420, good machinability and wear resistance, good resistance to corrosion. C:0.49, si:0.50, Mn:0.50 80 Cr:13.00

420 stainless steel, is one of steels stainless steel martensitic most widely used for the manufacture of knives, also for all kinds of surgical instruments, kitchen knives, scissors and blades.

Its main features:

- Good wear resistance.

- Good edge retention.

- high corrosion resistance.

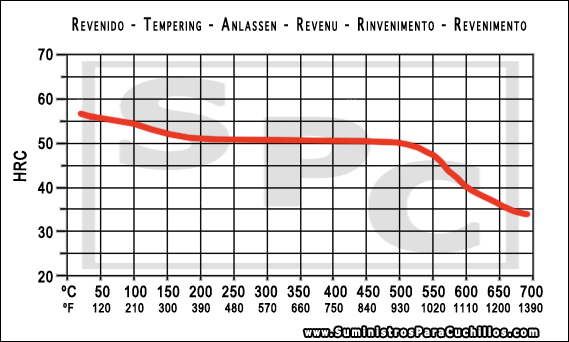

- Up to 57 HRC.

Chemical composition (%): C: 0.49, Si: 0.50, Mn: 0.50, Cr: 13.80

Polishing, or at least the fine sanding of all products manufactured with this steel, to maximise resistance to corrosion is recommended. In this sense, tempering and annealing at low temperatures, it is recommended to improve resistance to corrosion, high temperatures form a matrix of chromium carbides, which depleted the content in chromium, reducing the corrosion resistance.

This steel is recommended for beginners with stainless steel, its degree of difficulty of work is medium-low.

Annealed (soft), is provided to facilitate the work, since tempered once is very difficult work.

Heat treatment:

- Forging: 850 to 1150 ° C. Very slow cooling in furnace or insulation materials (sand, salt, mica).

- Normalizing: 750 to 850 ° C. To eliminate the structural tensions caused by forging or roughing. Preferred time, 1 hour.

- Hardening (oil): 980 to 1030 ° C. Preheating to 850 ° C, stabilized temperature, thermal jump to temple, reached temperature, keep at least 1 minute per millimeter, minimum immersion time 20 minutes. Cooling in oil 150 - 180 ° C to reduce thermal shock, keep cool for 3 to 5 minutes, then move to the tempering. 54 to 57 HRC hardness.

- Tempering: slow heating to the temperature of tempering (see the temperature chart). Recommended temperature range from 100 to 190 ° C, (corrosion resistance). Reached temperature 5 minutes per mm, the minimum recommended time is 50 minutes.

Quenching and tempering is recommended in atmosphere conservative, see tempered blade. This is the recommended thermal treatment, there are others. Temperatures, times or form of realization of it, depending on your needs you can vary or experience in such process.

MATERIAL CUT THROUGH MECHANICAL PROCESS MAY HAVE BENT (NOT COMPLETELY FLAT).